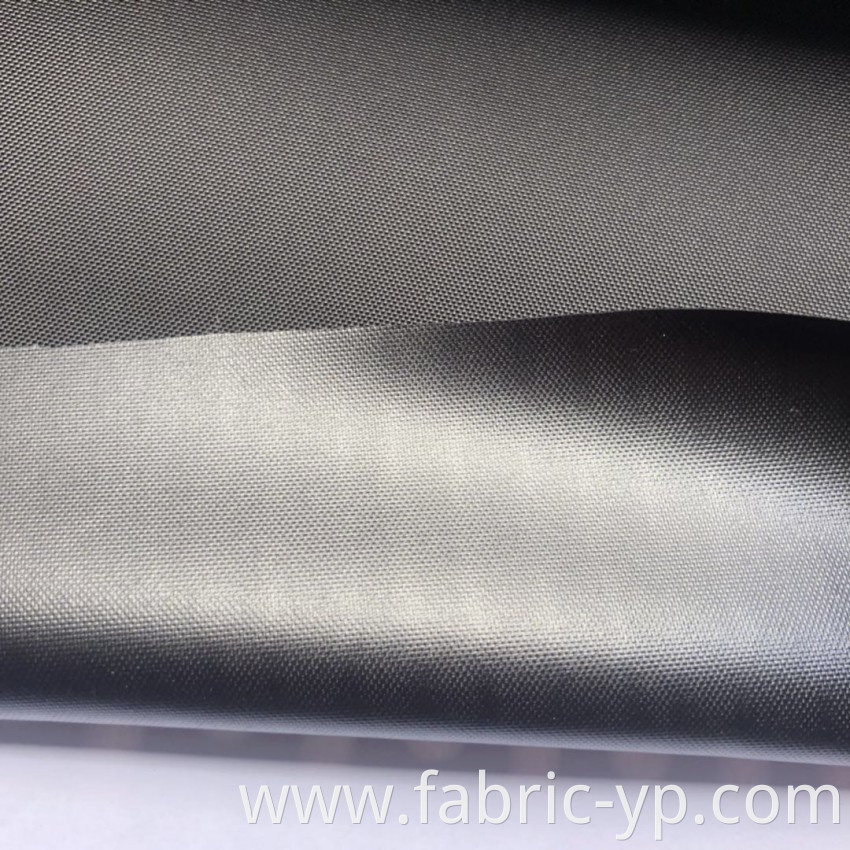

100% Nylon Oxford Fabric

Get Latest Price| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean |

Supply Type: Make-To-Order

Characteristic: Breathable, Water Resistant, Waterproof, Anti-Uv, Windproof, Stain Repellent

Craft: Woven

Style: Plain, Yarn Dyed

Types Of: Taffeta Fabric

Certification: Oeko-Tex Standard 100

Use: Baby &Amp; Kids, Sportswear

Coating Type: Pvc Laminated

| Selling Units | : | Meter |

Temporary flame retardant finishing: After finishing, the fabric can maintain excellent fire resistance, but the flame retardant effect will disappear after washing. Generally, the number of washable times is less than 15 times. After a period of time, it must be re-fired to restore fire performance. Such finishing agents are: metal oxides and halides of titanium and antimony, ammonium hydrogen phosphate and amine sulfamate, boric acid, borax, etc. This type of finishing agent is mainly suitable for curtains, curtains, and decorative fabrics that are not often washed.

Semi-durable flame retardant finishing: After finishing, the flame retardant effect can be maintained for a long time, but it can disappear after multiple washings. Generally, the washing resistance is 15-50 times. The most frequently used finish of this type is a mixture of tetramethylol chloride and dicyandiamide.

Durable flame retardant finishing: The durable flame retardant finishing agent uses chemical methods to polymerize or copolymerize inside or on the surface of the fiber to form a layer of polymers that are insoluble in water and general solvents, or use latex resin to dissolve insoluble materials. The water-soluble flame retardant finish adheres to the fibers. The most commonly used finishing agent of this type is tetrahydroxymethyl phosphorous hydroxide. The new flame retardant system should be developed in the direction of halogen-free, low-smoke, and non-toxicity. The flame-retardant finishing agent used for flax fabrics aims to improve the comprehensive flame-retardant performance of flax fiber fabrics while achieving green environmental protection.

No.: nl210-1

Product Name : 210D Nylon Oxford PU coating

Gram weight : 95gsm

density : 114T

Yarn weaving : 190D*190D

Composition: 100%n

width of cloth : 148cm

Finishing: dyeing + waterproof + coating

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.