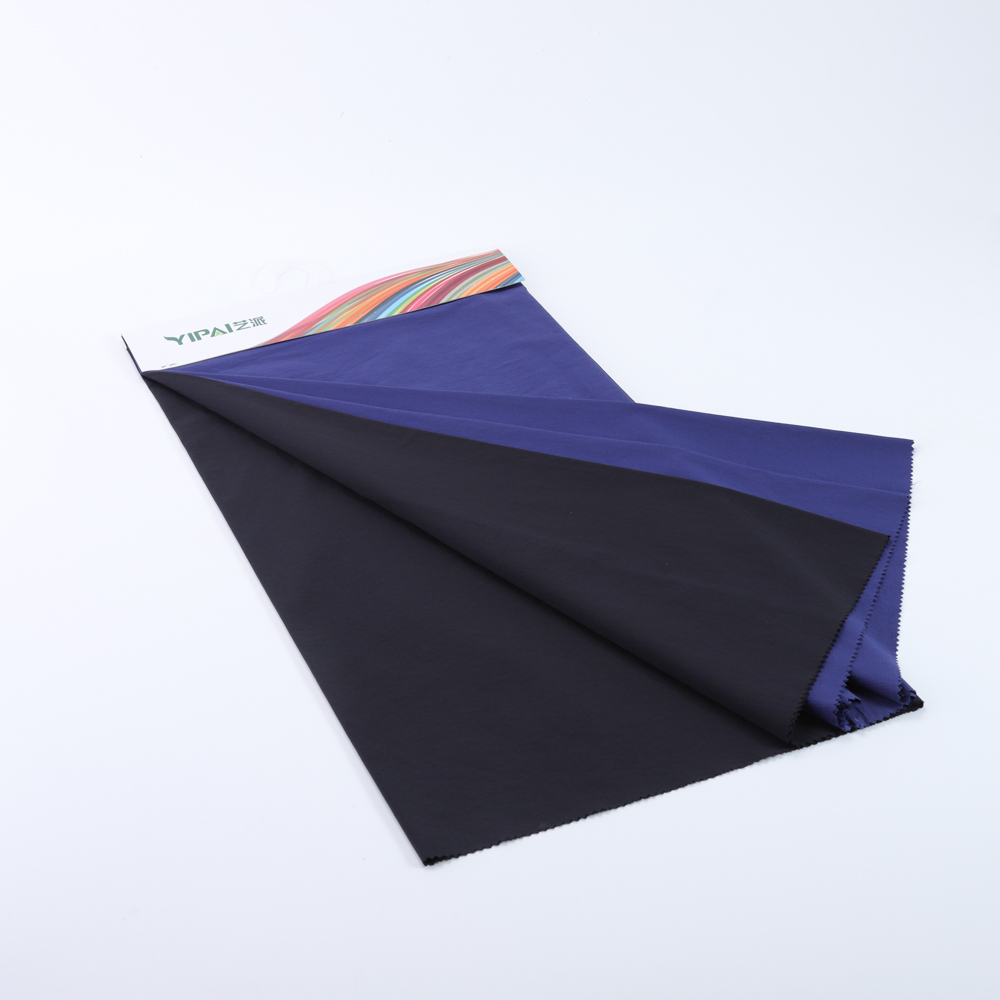

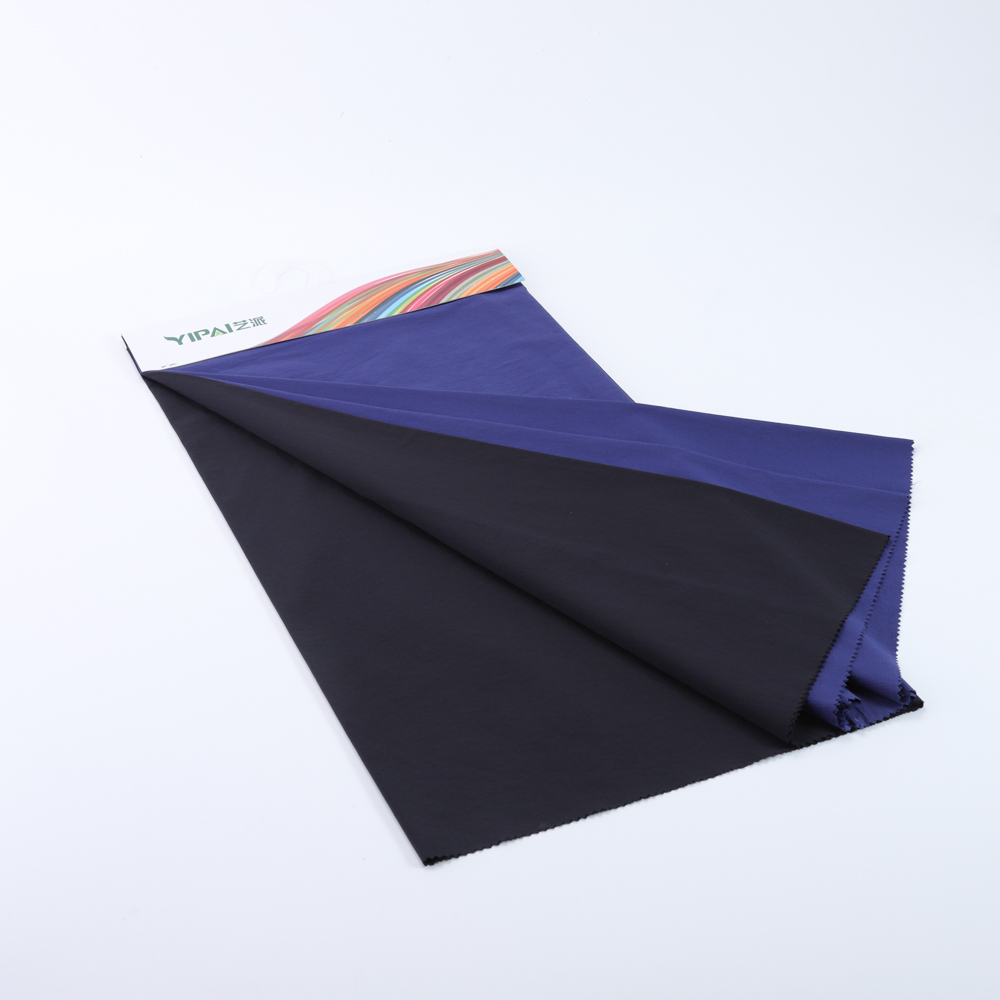

The textile industry has always been at the forefront of innovation, constantly striving to develop fabrics that cater to the evolving needs of consumers. In recent years, there has been a growing demand for fabrics that offer enhanced functionality, sustainability, and comfort. In response to this demand, textile manufacturers have introduced three groundbreaking fabrics - Waterproof Breathable Fabric, Recycled Fabric, and Anti-Static Lining Fabric. These fabrics are revolutionizing various industries, including outdoor apparel, fashion, and industrial sectors, by offering unique properties that were previously unattainable. This article delves into the characteristics, manufacturing processes, and applications of these remarkable fabrics. Waterproof Breathable Fabric is a game-changer in the textile industry, as it combines two seemingly contradictory properties - waterproofness and breathability. Traditional waterproof fabrics were often non-breathable, leading to discomfort and excessive sweating. However, the advent of Waterproof Breathable Fabric has eliminated this issue, allowing for optimal moisture management while providing protection from external elements. The manufacturing process of Waterproof Breathable Fabric involves the integration of a microporous membrane or coating onto the fabric surface. This membrane or coating consists of microscopic pores that are small enough to prevent water droplets from penetrating the fabric but large enough to allow water vapor (perspiration) to escape. This unique structure ensures that the fabric remains waterproof from the outside, while moisture generated by the body can easily evaporate through the fabric, keeping the wearer dry and comfortable. Waterproof Breathable Fabric finds extensive applications in outdoor apparel, including jackets, raincoats, and hiking gear. These fabrics are also utilized in the medical industry for manufacturing surgical gowns and drapes, ensuring protection against fluids while maintaining breathability. Additionally, this fabric is utilized in the manufacturing of tents, backpacks, and footwear, providing durability and comfort in extreme weather conditions. The textile industry has been under scrutiny for its environmental impact, particularly due to the excessive use of natural resources and the generation of textile waste. To address these concerns, textile manufacturers have introduced Recycled Fabric, which is made from post-consumer and post-industrial waste materials. This innovative fabric not only reduces the industry's carbon footprint but also offers a sustainable alternative to traditional fabrics. The manufacturing process of Recycled Fabric involves collecting discarded textile products and waste materials, such as plastic bottles or industrial scraps. These materials are then sorted, cleaned, and processed into fibers through mechanical or chemical recycling methods. The resulting fibers are spun into yarns, which are further woven or knitted into fabrics. Recycled Fabric has gained popularity in the fashion industry, with many brands incorporating it into their collections as a sustainable option. This fabric is used in the production of clothing items, including t-shirts, jeans, dresses, and activewear. Additionally, it is also utilized in home textiles, such as bedsheets, curtains, and upholstery, contributing to a more sustainable and eco-friendly lifestyle. Static electricity is a common issue in various industries, including electronics, automotive, and manufacturing. Anti-Static Lining Fabric has emerged as a solution to this problem, offering protection against static discharge while providing comfort and durability. The manufacturing process of Anti-Static Lining Fabric involves the incorporation of conductive fibers or coatings into the fabric structure. These conductive elements help dissipate static charges, preventing the build-up of electrical potential on the fabric's surface. The fabric's conductivity can be adjusted based on specific requirements, ensuring effective static control. Anti-Static Lining Fabric finds applications in various industries, including electronics manufacturing, where it is used in the production of garments worn by workers to prevent damage to sensitive electronic components. It is also utilized in automotive interiors, where static discharge can interfere with electronic systems. Furthermore, this fabric is employed in cleanrooms, laboratories, and other environments where static control is crucial. The introduction of Waterproof Breathable Fabric, Recycled Fabric, and Anti-Static Lining Fabric has significantly transformed the textile industry. These fabrics offer unique properties and cater to the growing demand for functionality, sustainability, and comfort. Waterproof Breathable Fabric provides protection against external elements while allowing moisture to escape, ensuring optimal comfort. Recycled Fabric offers a sustainable alternative to traditional fabrics, reducing the industry's environmental impact. Anti-Static Lining Fabric addresses the issue of static electricity in various industries, providing protection and safety. The adoption of these innovative fabrics in different sectors showcases the industry's commitment to meeting consumer needs while embracing sustainable practices.